OTR 300 – 400 – 500 – 600 type VACUUM SYSTEMS

The Company STIG SRL has created a new business unit “STIG VACUUM SYSTEMS” with the aim of designing and manifacturing vacuum units for applications in various indutrial sectors.

The Vacuum Systems are designed and produced in the production unit of Fontanellato (PR). Thanks to the know how acquired by their technicians during more than 30 years of experience in the vacuum field, mainly with liquid ring vacuum with total recirculation of oil or other liquids as sealing fluids recirculated over a heat excharger.

This systems are particularly suited for 24 hours heavy duty applications like for instance in the bricks and tiles industry, in the pasta production industry and plastic extruders.

Thenks to the possibility of using various sealing fluids according to the application and to the handled gas, the systems are suitable to be applied in almost all indutrial fields.

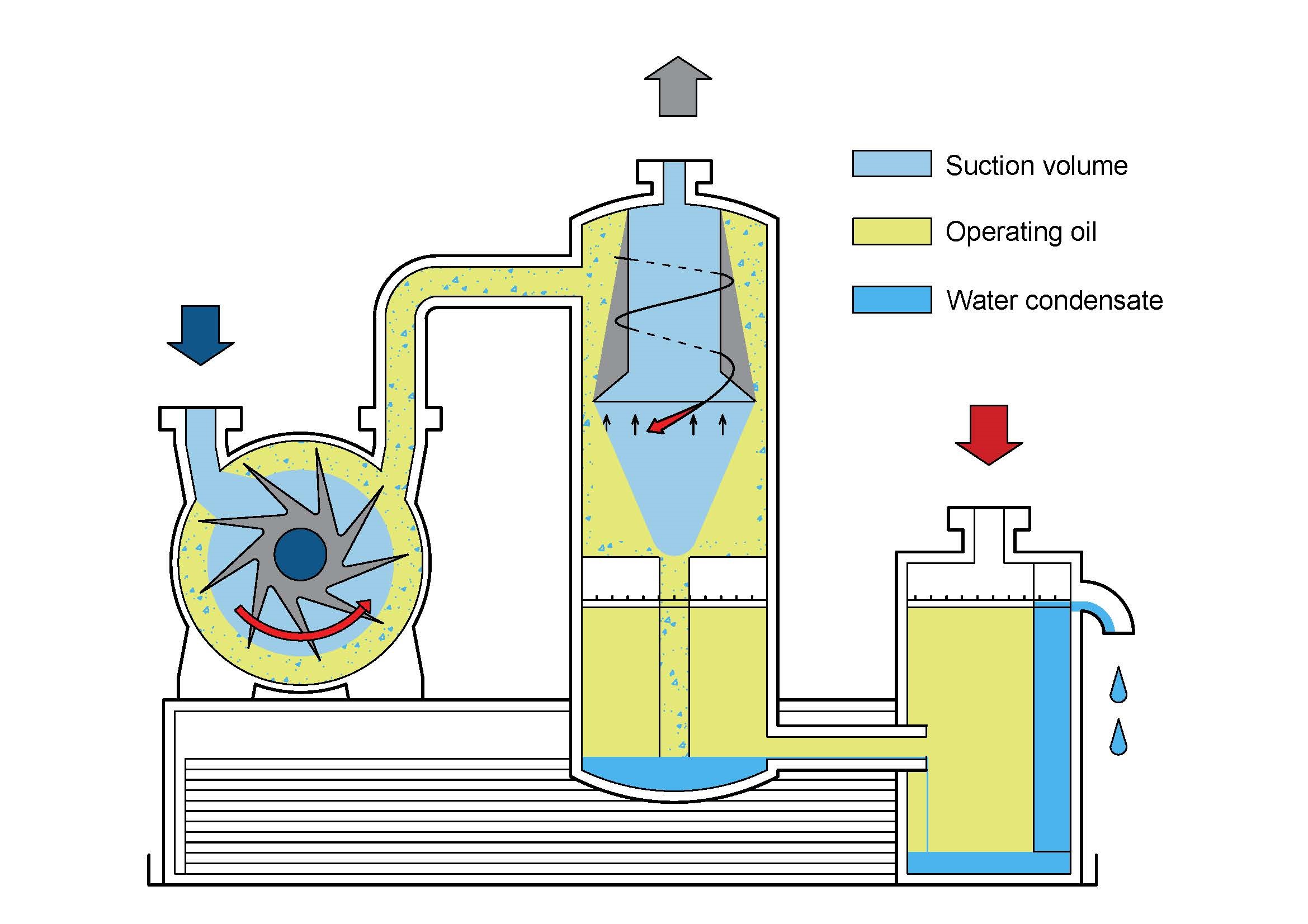

PRINCIPLE OF OPERATION

- The two stage liquid ring vacuum pump is continuisly fed with sealing oil , commonly known as “steam turbine oil” which guarantees a perfect hydraulic sealing of the liquid ring internally of the pump. It has a low vapour pressure at high temperatures thus achieving high vacuum degree. Moreover the operating oil keeps the pump internal parts continously lubricated thus avoiding their wear, it separates immediately the sucked condensate thus remaining clean from water.

- The oil cooling unit is composed by a oil circulating electropump (H) , a forced ventilation high efficiency heat exchanger (C ) in order to keep the oil temperature into the vauum

- Pump 32-35 °C above the ambient temperature

- The vertical cylindric oil/gas separator of cyclonic principle has the purpose to separate immediately the sucked gas , the possible impurities and the condensate

- from the operating oil

- The oil container (h), complete with level indicator, oil filling connection,oil drain valve (V2) , has a built in automatic discharge system of the sucked and separated from the oil condesate thru valve (V1)

- The horizontal and vertical suction separators (S1 S2) detect the bigger size impiurities and part of the sucked condensate before entering the pump

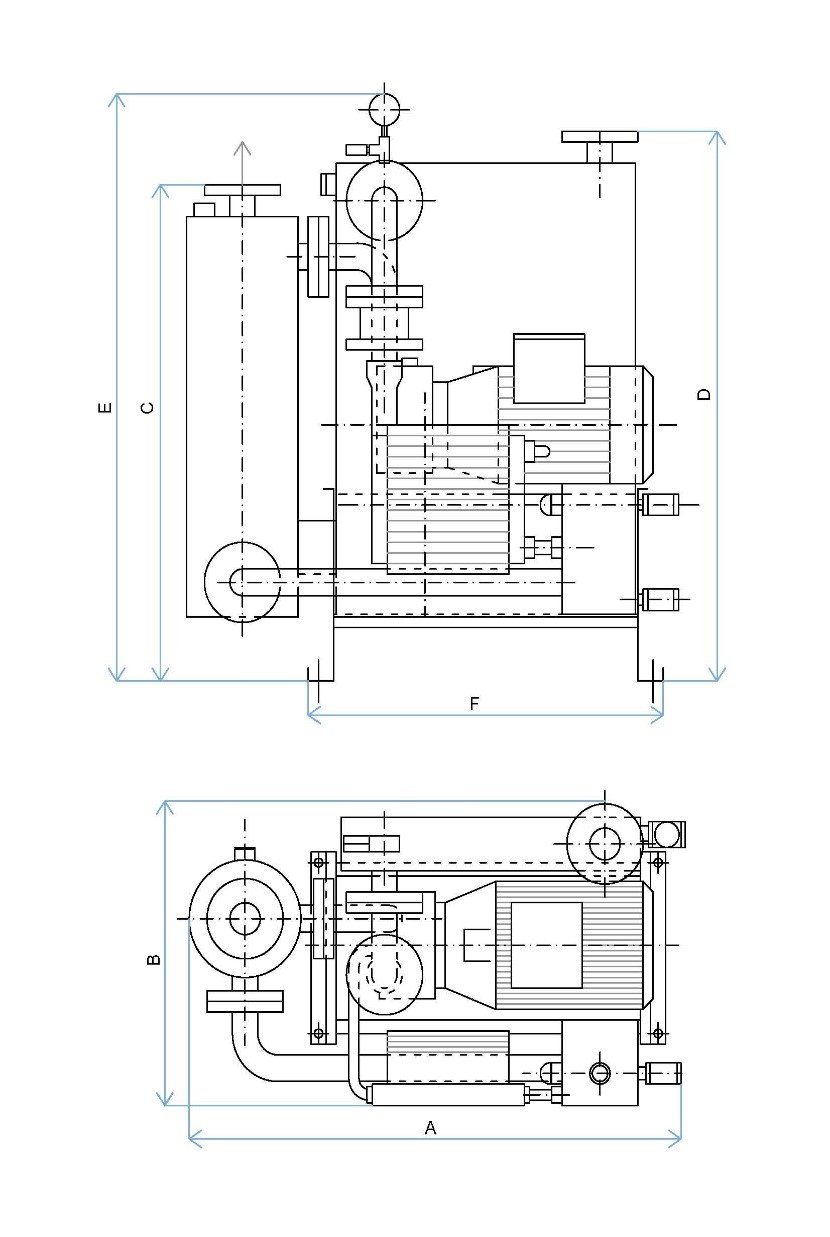

OTR 300.4

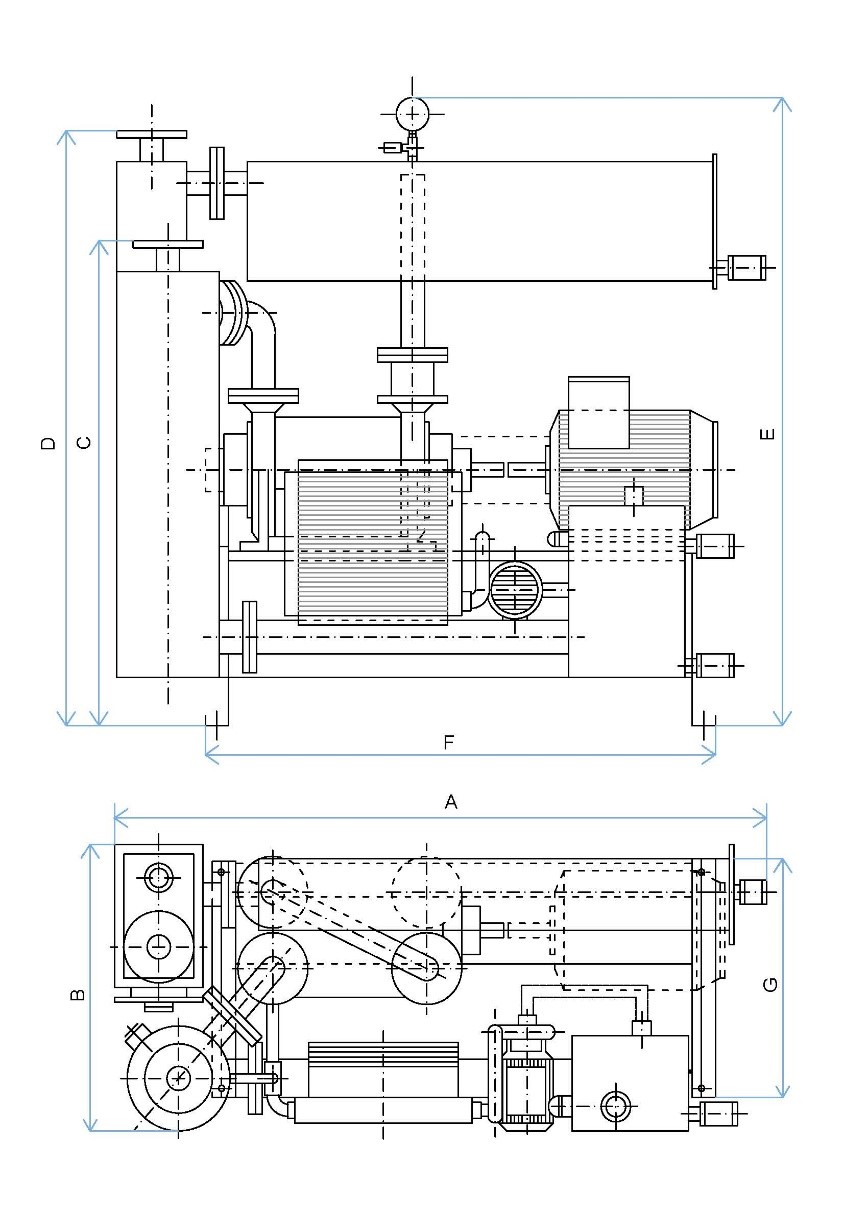

OTR 400-500-600

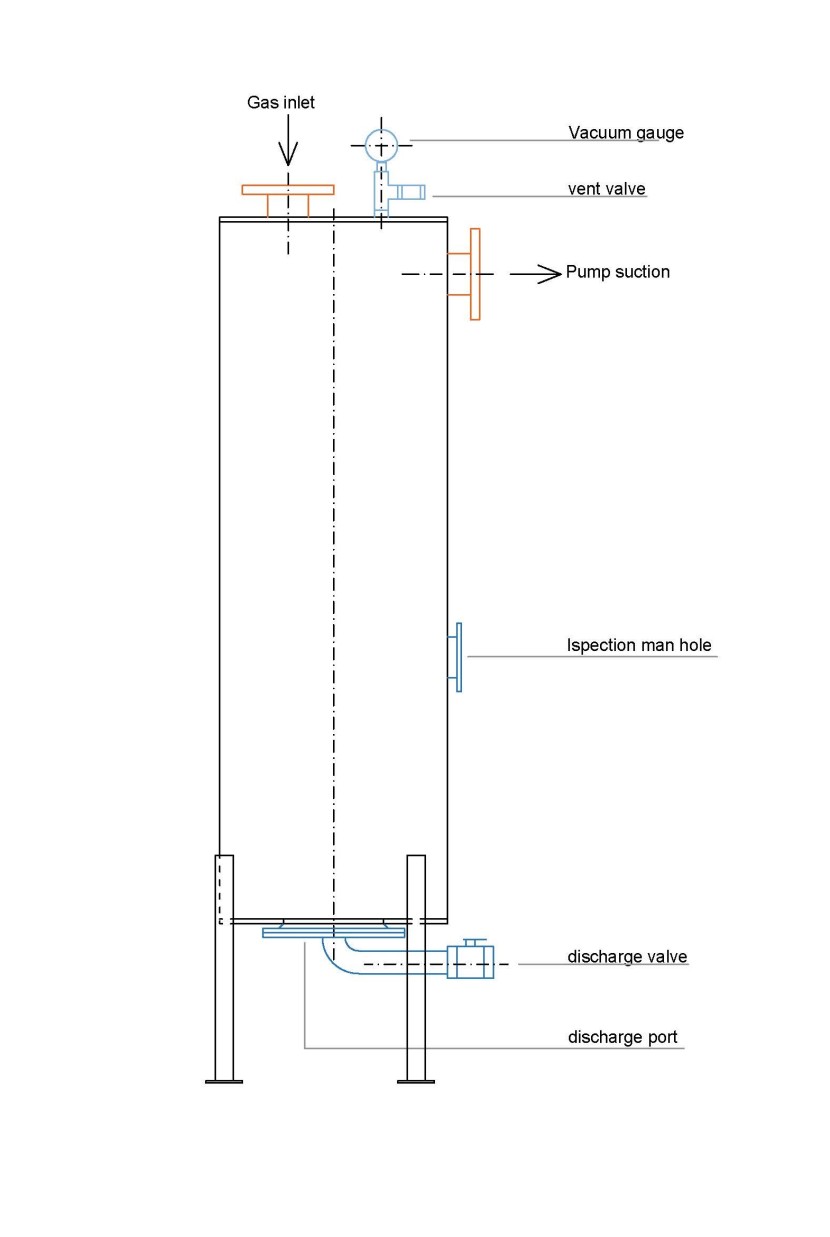

SEPARATOR TANK type PS